In the world of electrical wiring, aluminum has had its time in the spotlight. Widely used in residential construction during the 1970s, aluminum wiring gained popularity due to its cost-effectiveness. However, like any electrical solution, it comes with its own set of advantages and drawbacks. In this blog, we’ll delve into the pros and cons of aluminum wiring, helping you make an informed decision about its suitability for your home.

The Pros:

- Light as a feather:

Aluminium wiring takes the crown for being lightweight. Hence, it’s less strain on the electricians, resulting in a smoother installation process.

- Cost-effective:

If you’re on a tight budget, aluminium is your wallet’s best friend. It will keep the costs down for your electrical wiring.

- Malleable:

Aluminum bends and flexes, making it easy to work with. Voltage Electrical Contracting can mould it like clay, ensuring your wiring dreams become a reality without the headache.

- Good conductor:

Aluminium is an excellent conductor of electricity. Our friends at Voltage Electrical Contracting know how to orchestrate the perfect symphony of electrons, creating a harmonious electrical system.

- Good thermal conductivity:

Aluminum has impressive thermal conductivity, keeping things cool under electrical pressure even on the hottest days.

- Environmentally friendly:

Since aluminium is recyclable, it’s a more sustainable wiring solution.

- Corrosion resistant:

Properly installed, aluminium wiring can resist corrosion, ensuring your wiring stays shiny and robust.

- Lengthy Lifespan:

Aluminium wiring, when installed right, can stand the test of time.

- Compatibility:

Aluminium is compatible with modern electrical demands.

- Versatility:

From homes to buildings, aluminium wiring adapts to various settings.

The Cons:

- Expansion:

Aluminium expands and contracts with temperature changes. Voltage Electrical Contracting emphasises the need for proper installation to mitigate this issue.

- Corrosion:

Despite its resistance, aluminium can corrode if not handled with care. We advise regular checks to keep corrosion from creeping in.

- Compatibility:

Devices designed for copper might not support aluminium.

- Connectivity:

Aluminium connections can loosen over time.

- Oxidation:

Oxidation is the nemesis of aluminium. Voltage Electrical Contracting can help prevent oxidation for a long-lasting wiring setup.

- The Copper Controversy:

Copper vs. aluminium is an eternal debate. We can help you navigate the pros and cons so you can make an informed decision.

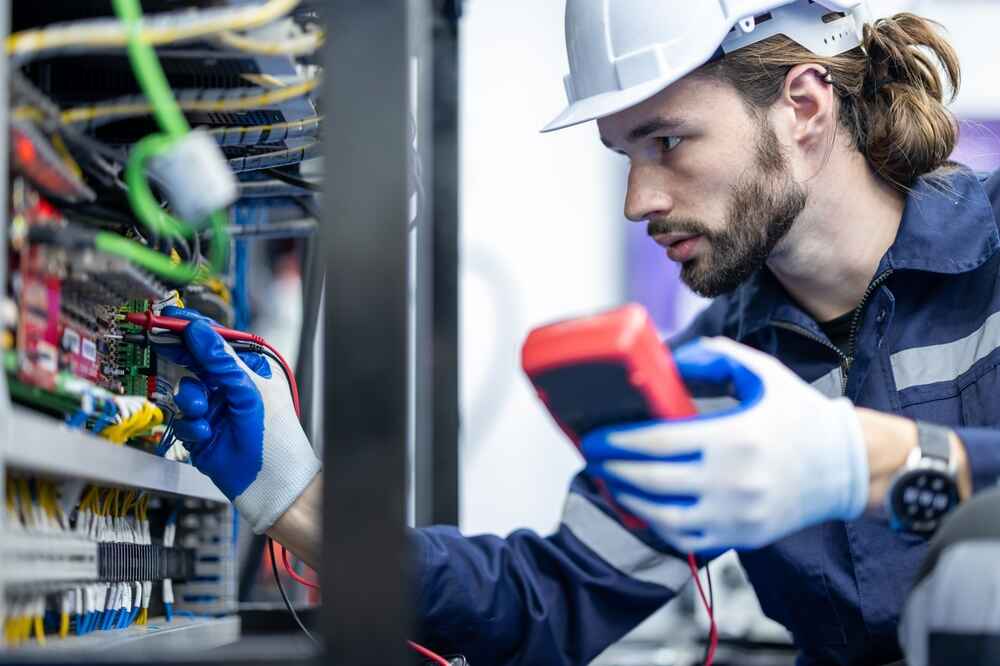

- Avoid DIYs:

Aluminium wiring isn’t the best for DIY projects.

- Fragile:

Aluminium is softer than copper, making it more susceptible to damage.

- Wear and tear:

Aluminium can experience more wear and tear over time and requires maintenance.

- Upgradation:

Since aluminium undergoes more wear and tear, it requires upgradation over time, which can be expensive.

And there you have it – the electrifying tale of aluminium wiring. As you navigate the pros and cons, remember it’s not just about the material but the expertise behind the installation. If you have an older home with aluminum wiring, it’s crucial to be aware of its limitations and consider consulting with a qualified electrician to ensure safety. And when it comes to consulting the experts, let Voltage Electrical Contracting in Perth be your electrical services provider. We are experts in all commercial, residential, industrial and brewery sectors! For more service-related queries, contact us today!

Like what you read? Read our other blogs here: