In the brewing industry, beer taste and quality are not the sole determinants of success. A complex interplay of machinery and technology goes unnoticed behind every pint. This blog post sheds light on a crucial yet often overlooked aspect of brewery operations: Electrical Maintenance. This unsung hero ensures the hops keep flowing and the beer pouring smoothly. So, let’s dive into the electrifying world of Electrical Maintenance in Brewery Operations and explore its pivotal role in delivering the perfect brew.

Brewery Equipment Installation and Automation:

To fully grasp the importance of electrical maintenance in brewery operations, it’s crucial first to comprehend the intricate interplay between equipment installation and automation. The machinery and equipment used in brewing are the backbone of the operation, ranging from fermentation tanks to bottling lines. Proper installation of these components forms the foundation of the brewery’s functionality.

However, brewery automation furthers this by streamlining processes and increasing efficiency. By automating routine tasks, brewers can focus on perfecting their craft. This perfect synergy between equipment installation and automation results in a seamless production line that guarantees consistent quality in every brew.

The Unsung Hero: Electrical Maintenance

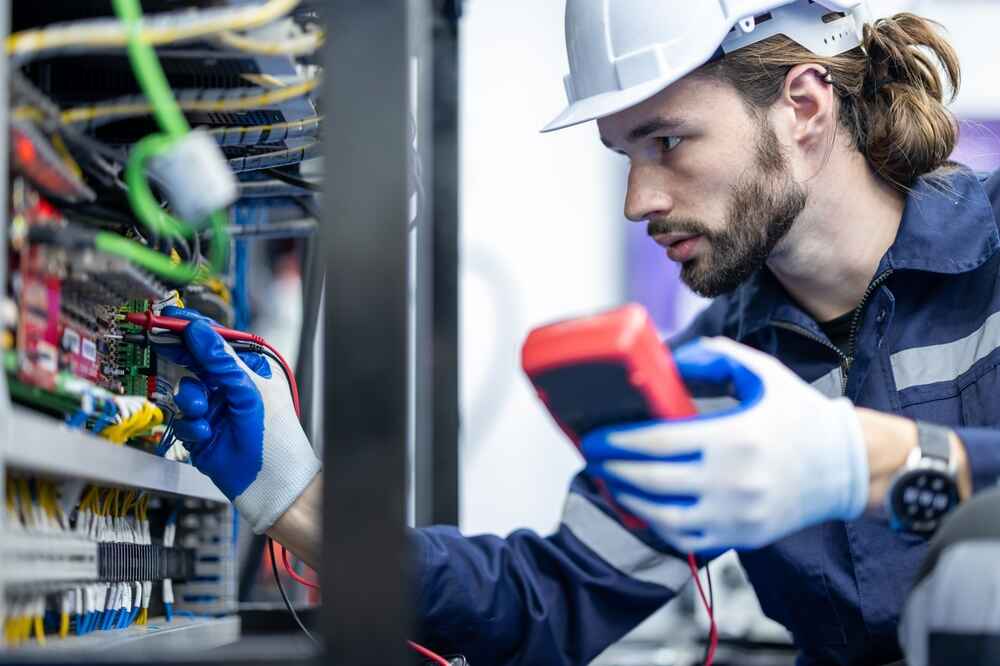

Behind the scenes, electrical maintenance emerges as the unsung hero of brewery operations. Electrical maintenance is a crucial aspect that keeps the gears turning, which ensures that all components function optimally, minimising downtime and maximising productivity.

Establishing a partnership with a trusted electrical contractor is important for breweries. In Perth, Voltage Electrical Contracting is known for providing exceptional electrical contracting services and high-quality product installations for residential, commercial, and industrial sectors. They are well-versed in bolstering brewery operations through their mastery of maintenance services.

- Services Included Under Brewery Electrical Services

- Micro-Brewery Electrical Installations & Maintenance

- Brewing Process Electrical Installations & Maintenance

- Pack-Line Equipment Electrical Installations & Maintenance

- Water Treatment Electrical Installations & Maintenance

- Can, Bottle & Keg Filler Electrical Installations & Maintenance

- Breakdowns & Fault finding

- Motor Control

Preventive Measures and System Optimisation:

The adage “prevention is better than cure” holds in brewery electrical maintenance. Regular check-ups and preventive measures can identify potential issues before they escalate into costly problems. Beyond just troubleshooting, electrical maintenance also involves system optimisation. As technology advances, keeping brewery automation systems up to date is vital. Electrical contractors like VE specialise in seamlessly integrating new technologies into existing setups, providing breweries a competitive edge in an ever-evolving market.

In brewing, the intricate tapestry of operations requires seamless functioning to ensure success. While the spotlight may shine on equipment installation and automation, the silent efficiency of electrical maintenance champions the competitive brewing world. And when it comes to trusted partners in this process, Voltage Electrical Contracting stands out.

As breweries in Perth and worldwide evolve, electrical maintenance becomes even more critical. It’s an essential partnership between craftsmanship and technology, with electrical maintenance guiding the way towards brewing success. Trust in the experts at Voltage Electrical Contracting to keep your brewery operations running smoothly so you can focus on crafting the perfect brew.